Samsung

The World’s First 3nm Memory Chip: Samsung To Start Mass Production From This 30th June

Highlights

- Samsung has prepped up and is ready to begin the mass production of 3nm memory chips starting this June 30.

- 3nm chip would foster a 30% performance increase, a 50% energy consumption reduction, and up to 80% higher transistor density.

- Samsung could delay the fabrication process turned out to be baseless rumors, according to insider sources.

So developments and again developments, rumors and expected dates. This was all going around this month for the semiconductor industry.

But finally, today, several reliable sources informed the media that Samsung has finally prepped up and is ready to begin the mass production of 3nm memory chips starting this June 30.

Samsung is going to use an advanced GAAFET (gate-all-around field-effect transistor) architecture compared to its archrival TSMC’s FinFET (fin field-effect transistor) for the fabrication method.

This, when completed, would foster a 30% performance increase, a 50% energy consumption reduction, and up to 80% higher transistor density, according to Samsung.

If this goes according to schedules, then Samsung will become the first manufacturer of semiconductors to start using gate-all-around field-effect transistor (GAAFET) architecture with its impending 3 nm fabrication process.

Samsung announced in April this year that it will work on 2 nm by 2025. Before this, Samsung also informed in April that it would start to work on the 3nm chips 3GAE (3 nm-class gate-all-around early) fabrication process, starting in mid-2022.

It came to light during the 10 days US president’s visit to S.Korea in Samsung’s electronic plant on May 20, and it’s believed that Samsung presented the world’s first GAA-based 3-nano chip prototype.

According to Taiwanese market researcher TrendForce, Samsung has made $5.3 billion in foundry revenue in Q1 March, which is less than 3.9 percent from the previous three months, while market share plummeted from 18.3 percent to 16.3 percent in this time.

Furthermore, this year, the Samsung group ranked 22nd position from 15th compared to last year, making it drop down 7 steps on the global market cap in comparison to last year’s position with a market value of $342 billion as of March.

However, amid this, rumors were floating that Samsung Electronics could halt the process because of expected earnings generated over a particular period and production problems regarding raw materials availability, i.e., yield issues due to the current ongoing war and semiconductor production crisis due to the pandemic.

Amid these up & downs, there were predictions that things weren’t going well for the Korean conglomerate, but its advancement in technology and resolution it projected could still secure it a leading position against the rivals in this business, namely USA’s Intel & Taiwanese TSMC.

TSMC is expected to mass-produce the first-gen 3nm chips (N3) for its customers in early 2023 & 2nm by 2025. TSMC informed at TSMC Technology Symposium 2022.

Although it was believed that Samsung could delay this process until the latter end of this year, predictably in Q3 2022, however, these just turned out to be baseless rumors, according to insider sources.

Samsung has already devised a roadmap for its investment in texas for the foundry factory. A $17 billion Texas microprocessing chip plant. Also to note, recently, Samsung announced a $356 billion investment pledge for the chip, bio, and IT sector over the next five years, of which 80 percent will go to facility and R&D investment. This seems to impact the tech industry’s future.

It’s just about a little time. According to the sources, Samsung Electronics is set to officially announce volume production of GAA-based 3-nm semiconductors on June 30.

Readers can also learn about the TSMC vs. Samsung rivalry & more about the chip fabrication process from the below links.

Samsung

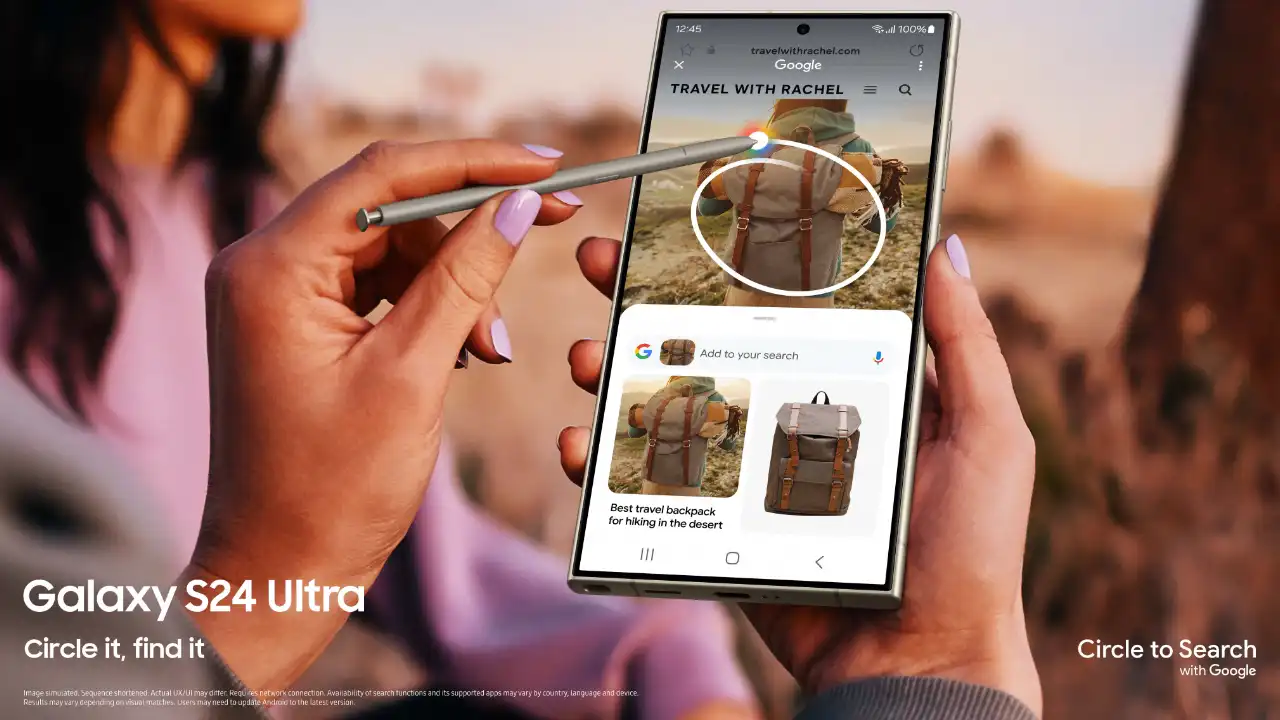

Samsung Galaxy AI’s Circle to Search Could Soon Get a new Upgrade

Samsung introduced its Galaxy AI, which consists of several generative AI features. Circle to Search with Google is one of the most admired features. Now, it may soon get a major upgrade based on comments made in a recent Made by Google Podcast episode.

The Circle to Search with Google feature is available on both Galaxy S24 and Pixel 8 devices, and reports are saying that soon it could get a big usability upgrade and become a bit harder to trigger by accident. The forthcoming changes will be based on comments made in a recent Made by Google Podcast episode, in which host Rachid Finge spoke with Erin Lynch and Alistair Pott, who worked with the Circle to Search development team.

During the podcast, Lynch admits that the circle to search with was quite easy to activate by accidental touches as it’s located on the same gesture bar or home button that users use for other purposes most of the time. Regarding this, she and Pott assured that Google was working to fix it to avoid accidentally activating this feature; however, they didn’t elaborate on the assurance.

However, the Circle to Search feature already received an update that gives it the power to translate circled text. It is expected that the future update could be a combined search and lens results page while using the Circle to Search feature instead of having them separate as they are now.

Apart from this, the podcast unveiled a few interesting twists regarding how Circle to Search came to be. It came to light that it is based on Google Lens and has been in development since January 2023, after Google staffers were actively working on how Lens became more readily available outside its app.

Samsung

Samsung Ecosystem Matching Apple’s Tight Integration

Samsung offers a unique ecosystem that delivers a distinct experience as compared to its competitor, Apple.

Samsung has its own OG (original) ecosystem and is even better than its rival Apple in functionality. It’s not just a phrase, but here we are mentioning some of the key reasons why, in many ways, it’s better. However, Samsung lagged behind Apple in delivering a coordinated ecosystem with well-designed gadgets, but that doesn’t mean Samsung has a lack of willpower.

Now, Samsung has covered the gap in some areas and even exceeded Apple in others. Check out the key facts mentioned below:

Samsung’s versatility over Apple

From then to now, Apple has only offered limited models, tons of monopolies, and high-budget. On the other hand, Samsung offers dozens of phones in any size and budget you could prefer. The same fact is true of tablets: Apple’s lineup has gotten more complex, but Samsung is still offering more options.

Samsung has an extra lineup: ‘Foldable phones’ –

Samsung offers dozens of foldable phones; one is a book-style foldable, and the other is a flip, such as the Galaxy Z Fold 5 and the Galaxy Z Flip 5. Also, we are gearing up for the latest Galaxy Z Fold 6 series. Whereas Apple has yet to offer its very first foldable device. Samsung even offers a phone with a built-in stylus, the Galaxy S Ultra’. Apple does not do that sort of thing, ever.

Samsung offers one Galaxy for every Apple device

Samsung offers one Galaxy for each Apple device; for instance, for the Apple Watch, Samsung offers the Galaxy Watch; for AirPods, there’s the Galaxy Buds; for MacBooks, Samsung laptops run Windows; or you can launch Samsung DeX on a Galaxy Tab S9 Ultra. Both brands offer monitors, keyboards, and mice. Somehow, Samsung lacks a VR headset compared to Apple’s Vision Pro, but its ecosystem expands to smart home appliances and even TVs.

Galaxy’ are more compatible than Apple devices.

Comparing the latest devices of both brands, the iPhone 15 Pro Max and the Galaxy S24 Ultra, Samsung offers a better display, more RAM, and faster charging speeds than the iPhone 15 Pro Max.

Jumping on tablets! Galaxy S9 Ultra versus iPad Pro: Samsung offers a 14.6-inch display, whereas Apple offers a 12.9-inch. It is crystal clear that Samsung is winning here.

Samsung’s Galaxy devices are now capable of delivering similar smooth connectivity features as Apple’s. Both Apple and Samsung’s ecosystems let you share files, switch audio between devices, and more; the only difference appears in the way of functionality or features’ names.

Samsung has more features than Apple

Samsung offers more features as compared to Apple; for instance, Samsung’s DeX offers a desktop-like experience on phones and tablets and multitasking with features like resizable windows, app minimization, and a taskbar. Samsung prioritizes a UI to optimize multitasking, whereas Apple boasts a supreme app ecosystem. Samsung has yet to offer a traditional desktop operating system; currently, it integrates heavily with Microsoft’s.

Unlike Apple’s focus on supreme integration within its ecosystem, Samsung prefers to go with quality devices that are capable of performing well independently. Samsung avoids monopolies; you can seamlessly connect your Galaxy devices with non-Galaxy devices like Windows PCs.

These are key facts that transparently prove Samsung’s ecosystem is far better than Apple’s.

Samsung

Samsung Assembles Team Galaxy for Paris 2024 Olympics!

Samsung UK announced its Team Samsung Galaxy roster in the UK for the Olympics, 100 days before the Paralympic Games in Paris 2024.

This new announcement from Samsung UK coincides with Samsung’s global theme, “Open Always Wins.” Samsung has already unveiled its global ambassador line-up earlier this year, made up of more than 25 Olympians and Paralympians, which include UK representative Sky Brown, British skateboarding star and long-standing brand ambassador, next to breakdancer Karam Singh.

Team Samsung Galaxy presents its UK roster of outstanding athletes who represent the aspect of ‘Open Always Wins’.

Kadeena Cox (parasport athlete) is a two-sport world and paralympic champion who spearheads the paralympic movement, embodying strength and resilience. She inspires others to push boundaries. The next is Lola Tambling (Skateboarder), a rising skateboarding star full of fearless spirit who embodies the sport’s dynamism, inspiring the future generation. Joe Hinson, a skateboarder and national champion, is full of enthusiasm that reflects Samsung’s open-minded culture. Bethany Shriever, a cyclist and BMX racer, made history by winning gold at Tokyo 2020, setting a new record for British BMX racing.

The Director of Marketing, Omnichannel, and Head of Ireland, MX Division, stated that “These athletes perfectly embody the spirit of ‘Open Always Wins’, which is all about defying limitations, embracing innovation, and inspiring others to achieve their dreams. We’re fully behind these incredible people as they strive for their dreams, and we know the nation will be behind them too. We can’t wait to see them perform in Paris!”

Team Samsung Galaxy will present as the primary voices for ‘Open always wins,’ and by sharing their journeys, they will demonstrate how Samsung is helping athletes and fans just to open up new opportunities through its technologies.