Samsung

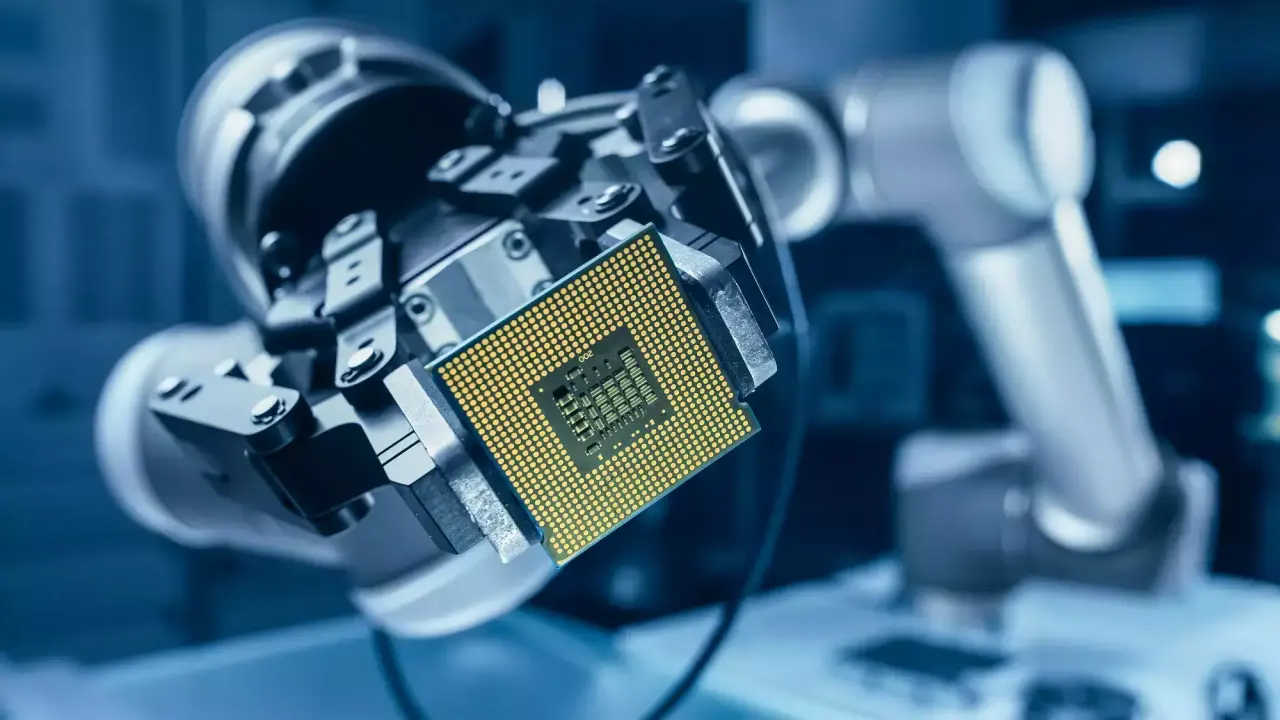

Samsung Ramps Up 3nm Chip Production to Compete with TSMC

Samsung is eagerly trying to compete with the biggest chip manufacturer, TSMC. To do that, the company has increased the production of the 3nm chip. However, it is still not achieving the same yield rate as TSMC.

According to a tipster, @Teck_Reve, Samsung’s initial yield rate was 10 to 20%, which has now increased by over threefold, but he didn’t mention the exact amount of production increase.

If you don’t know about the yield rate, it is a measure of the usable chips manufactured at a facility. It is calculated as the percentage of the total number of chips produced. If the yield rate is high, the number of defective chips is low. Ultimstrly it mrsdutr the efficiency of the chips production.

The Korean giant has started making 3nm chips in 2022, but it has struggled to achieve the yield rate. It has transitioned from the FinFET transistor architecture to the more advanced GAA architecture, but Samsung hasn’t achieved the desired yield rate while at the same time the TSSMC, with the same 3nm fabrication manufacturing, has achieved the efficiency and has enjoyed the yield.

However, if the report is inaccurate, there are some positive signs that Samsung is trying to fill the gap between the efficiency of manufacturing. As per the tipster, the Korean giant is providing the 4nm chips, which employ the FinFET architecture. The power efficiency and logic area have increased by 20–30%. If this happens, the company will get a major advantage to edge the 3nm semiconductor market.

According to a recent report, Samsung has informed its customers about a rebranding of its 2nd-generation 3nm process. The company will call the 2nm process instead of the 2nd generation 3nm process, technically a 3 nanometer process, but the Korean firm is renaming it to 2nm. It is confusing that the company is taking this step, but the real 2nm chips will be available next year’s second quarter.

Samsung

Samsung Decided To Focus On AI For Next Wearables

In a meeting at Samsung Medical Center in Seoul, Dr. Hon Pak, SVP, and head of Samsung’s Digital Health Team discussed AI, wearables, and their ability to revolutionize healthcare.

The discussion in the meeting emerged around two key themes: first, how advancements such as generative AI could be harnessed to improve healthcare, and second, Samsung’s ability to contribute to the future of healthcare was a key focus, possibly due to their ongoing innovations.

Professor Myung Jin Chung, Director of the Samsung AI Research Center at Samsung Medical Center, highlights the necessity of “lifelog” data assembled by wearable devices for a better understanding of the patient’s medical history. According to him, the future of AI is to extract this information straight from the user’s daily life and offer a better understanding of their health status.

A cardiologist, Dr. Blum, states that it will be better to continue health monitoring through smartwatches, which is key for early disease detection. He also highlights scenarios such as high blood pressure and atrial fibrillation where previous intervention is essential. He believes that smartwatches can offer valuable data for doctors to understand the root causes of the disease whereas AI helps to analyze this data and translate it into actionable insights for patients.

A diabetes specialist, Dr. Klonoff, punctuates the growing use of glucose monitoring, not only for diabetics but also for those pursuing a healthier lifestyle. He also considers it an essential as well as powerful tool when combined with other health data such as sleep, blood pressure, and activity. It is expected that this data, analyzed by wearables and AI, could offer a better understanding of overall metabolic health.

Recent reports reveal that the South Korean giant is also working on the implementation of wearable technologies capable of reading the glucose levels of its users. Apart from this, the giant is also deciding to develop non-invasive solutions for blood glucose monitoring, which would lead the company to get ahead of its long-time rival Apple in this area.

Samsung

Samsung’s Galaxy Unpacked Event Scheduled for July 10th in Paris – Report

Samsung fans are eagerly waiting for the next Galaxy Unpacked event, which was previously supposed to be held in the second week of July. Now, finally, the exclusive date has been revealed for the event.

The Samsung Galaxy Unpacked event will take place on July 10, 2024, as the report says. The Korean giant is gearing up to introduce sixth-generation foldable phones and smart wearable gadgets.

- Galaxy Z Fold 6

- Galaxy Z Flip 6

- Galaxy Ring

This much-awaited Galaxy Unpacked event will take place in Paris. It appears to be a great choice, as Paris will host the 2024 Summer Olympics after that month, and Samsung is one of the leading worldwide sponsors of the games.

Before any official announcement, the leaks and rumors have already revealed much more regarding the specs, features, and design of the forthcoming devices, according to which the brand could also introduce an extra variant of the Flip 6 under the name Galaxy Z Fold 6 FE. This time, the giant will also reveal more about its very first Galaxy Ring.

Apart from these devices, we can also expect the Galaxy Watch 7 and at least one new pair of wireless earbuds to be introduced at the event; however, regarding these devices, nothing has officially been cleared yet, but it will be interesting to be a part of the event.

Samsung

Samsung Canada Introduces a New Loyalty Program – Samsung Rewards

Samsung Electronics Canada is launching a new loyalty program for Canadians called ‘Samsung Rewards.’

The aim behind launching this Samsung Rewards program for Canadians is to earn points whenever they purchase qualifying Samsung products online. Interested parties can then compile points online for future Samsung product purchases.

Canadian Samsung Galaxy owners with a Samsung Account can easily enroll in the program and collect points with each qualifying purchase made on Samsung.ca or the Samsung Shop Application, earning 1 Samsung Reward Point for every $1 spent on eligible products. Points can be delivered towards a purchase of eligible products on Samsung.ca and the Samsung Shop App.

The Vice President of the Direct-to-Consumer Division, Samsung Canada, Krista Collinson, stated, “As retail shopping habits continue to evolve, Samsung is committed to growing with our customers so that they have the best possible experience.”

You can enjoy the exclusive benefits by just following these simple steps:

First, join Samsung Rewards by creating a free Samsung account and enrolling in the Samsung Rewards program. If you already have your account, then just sign up for Samsung Rewards through your Samsung account by using the email associated with your account.

Secondly, earn points when purchasing on Samsung.ca or in the Samsung Shop App and automatically receive points on every qualifying purchase.

At last, redeem your points, log in, and select Samsung Rewards for payment at checkout to get a discount using your points.