Samsung

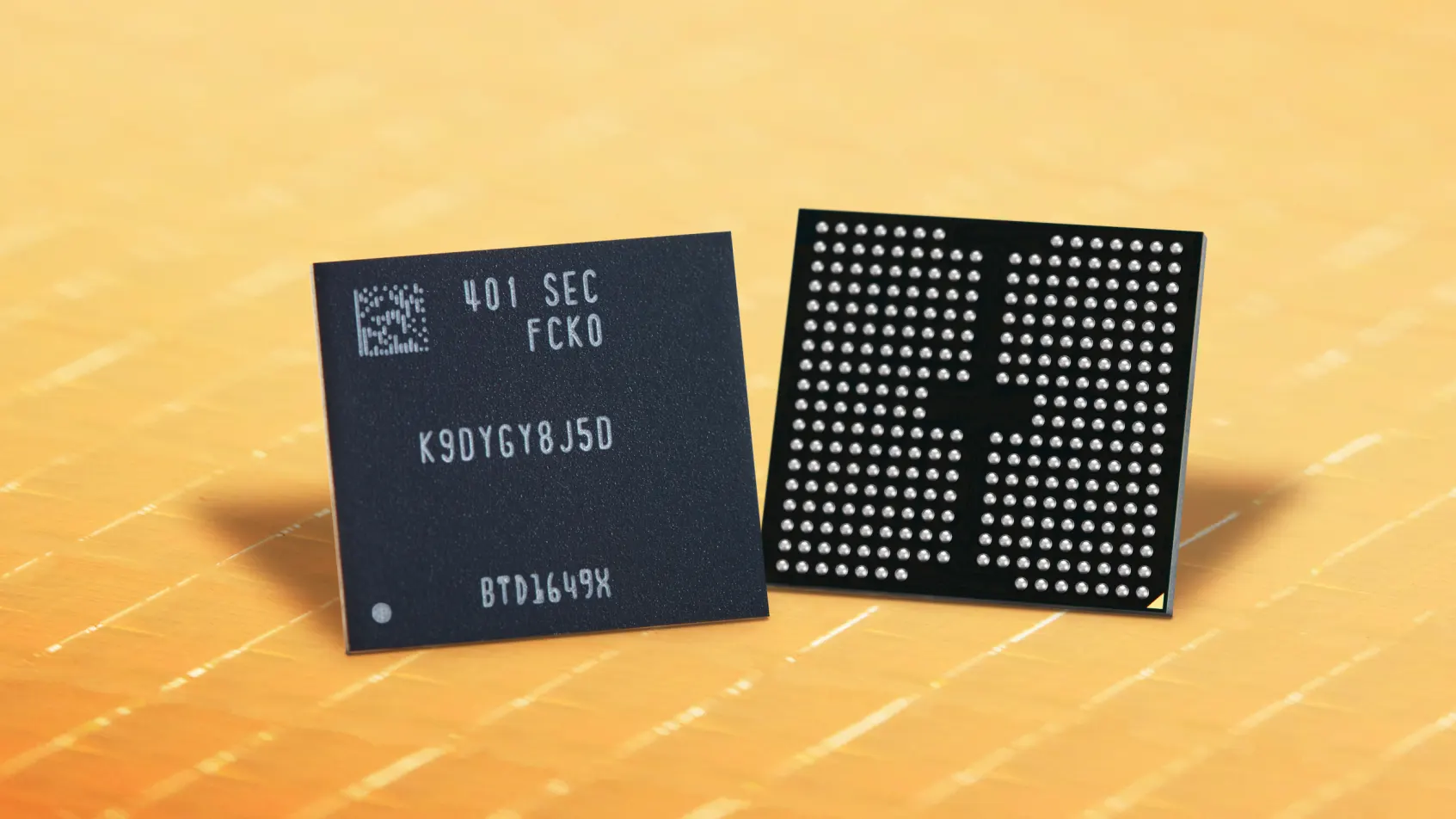

Samsung Electronics Begins Mass Production For 9th-Gen V-NAND

The Korean Electronics firm announced that it has begun mass production for its one-terabit (Tb) tripe-level cell (TLC) 9th-generation vertical NAND (V-NAND).

One of the key reasons for beginning this mass production is just to solidify its leadership in the NAND flash market. This 9th generation V-NAND flash memory has significant improvements. It offers a 50% increase in storage density compared to its predecessor, the 8th-generation V-NAND. This appears due to the tiny cell size and thinner design.

The Korean giant also executed new techniques for upgrading the reliability and lifespan of the memory cells while eliminating dummy channel holes, which significantly reduced the planar area of the memory cells. The Head of Flash Products & Technology of the Memory Business at Samsung Electronics, SungHoi Hur, stated, “Through our latest V-NAND, Samsung will continue to set the trend for the high-performance, high-density solid-state drive (SSD) market that meets the needs of the coming AI generation.”

Samsung‘s advanced ‘channel hole etching’ technology exhibits the brand’s leadership in process capabilities. This technology creates electron pathways by stacking mold layers and increases fabrication productivity as it authorizes simultaneous drilling of the industry’s highest cell layer count in a double-stack structure. As the cell layers increase, the capability to pierce through higher cell numbers becomes crucial, demanding more complicated etching techniques.

The 9th-generation V-NAND is enabled with the next-gen NAND flash interface, Toggle 5.1, which will help to support the increased data input and output speeds by at least 33% to up to 3.2 Gbps. The Korean giant plans to solidify its position within the high-performance SSD market by expanding support for PCIe 5.0.

With the advancement in low-power design, power consumption has also improved by 10%.

Samsung

Samsung Knox Achieved CC Certification for High-end Security Standards On 2024 TVs in Australia

Samsung Electronics has announced that Samsung Knox is uniting into its 2024 TV range and has achieved CC certification (Common Criteria) ahead of the product launch.

Samsung Knox is designed to keep in mind a security and management framework that arrives pre-installed on specific Samsung mobile devices. The CC certification is a term that refers to a worldwide program that establishes a hierarchical framework for security concepts and terminology for information technology (IT) products.

The key reason CC exists is to help assure consistent and rigid integrity evaluation standards for IT products and continue to help upgrade the efficiency of evaluation and certification. This certification is acknowledged by 31 countries worldwide. With upgraded evaluation and consistent standards, the CC aims to sustain confidence in the security of certified IT gadgets.

The CC certification comprises a Protection Profile (PP) and a Security Target (ST). Fortunately, Samsung Knox has met the security target and earned the standards for the CC.

The CC certification emphasizes three core security features of Samsung Knox:

- Tizen OS Monitoring: Samsung Knox helps to detect possible threats in real-time, flagging any unauthorized changes in critical sectors of Tizen OS, the core of Samsung TVs.

- Phishing Website Blocking: Samsung Knox justifies web pages accessed by users by anticipatory blocking any possible phishing sites to help safeguard user data and privacy.

- Enhanced Personal Information Protection: Samsung Knox will make sure to offer seamless protection of users’ crucial data through a connection with Samsung Knox Vault, a dedicated processor for security functions.

Samsung

Samsung Debuts WAD Interactive Display Series in the USA

Samsung Electronics is introducing a new Google EDLA-certified ‘WAD’ interactive display for classrooms as part of Teacher Appreciation Week.

This week is Teacher Appreciation Week (from May 6–10) in the U.S. Samsung appreciates teachers’ hard work and offers them new classroom technology, professional development assets, and discounts on goods.

Samsung debuted a new lineup of interactive displays for classrooms named the WAD series, certified by Google for educational use. They are available in three sizes and run the latest Android OS system.

- 65-inch, 75-inch, and 86-inch models

The WAD series interactive displays are intentionally designed to be easy for teachers to use. Since they are Google-certified, they work seamlessly with Google Classroom as well as Drive. The WAD series interactive displays feature various functionalities to boost student engagement and collaboration.

- Natural writing experience with an IR touch

- At least 40 students can interact together.

- Up to nine devices can share content on the display simultaneously.

- It offers a 3-in-1 USB-C port for connection with the support of 65W charging and HDMI output for sharing content.

Notably, the display can send critical messages instantly across all displays in classrooms and public spaces. The school leaders have the power to remotely monitor and control the display using Samsung’s Device Management Solution (DMS).

Samsung.com is offering an exclusive discount to educators and school administrators on a few devices. –

- Up to $600 off on particular curved and ergonomic Samsung monitors for helping with lesson planning, parent communication, and more.

- Up to 25% off popular models such as the WAC series and the Samsung Interactive Pro display.

As a part of the week’s promotions, teachers have the chance to earn a $50 Samsung Gift Card with purchases over $299.

Samsung

Samsung and O2 Telefónica Boost German 4G & 5G Network

Samsung Electronics and O2 Telefónica today announced that the brands have debuted their very first virtualized RAN (vRAN) and Open RAN commercial sites in Germany.

It is the first time that Samsung’s 5G vRAN solution is being used in Germany, which is using vRAN and Open RAN technology and is live in Landsberg am Lech, Germany, offering 4G and 5G services. At the moment, the facility is limited, but the network will be expanded to seven more sites in the area soon. Undoubtedly, this is an efficient development for open-RAN technology.

The Executive Vice President, Head of Global Sales & Marketing, Networks Business at Samsung Electronics, Junehee Lee, stated, “Samsung is setting new standards for excellence in the telecommunications industry with our innovative vRAN and open RAN capabilities. Celebrating Telefónica’s 100th anniversary, we are proud to be the key partner for O2 Telefónica on their trailblazing journey to usher in a new era of connectivity in Germany.”

O2 Telefónica is building an even more significant and futureproof network, leveraging modern and advanced technologies, open interfaces, and automation capabilities. Open RAN authorizes greater flexibility in the mobile network. Based on open interfaces, operators can merge network components from different providers and integrate them into their network.

Samsung is providing its market-leading 4G and 5G vRAN 3.0 solution and O-

RAN-compliant radios supporting low- and mid-bands (700MHz, 800MHz, 1.8GHz, 2.1GHz, 2.6GHz, and 3.6GHz), which include 64T6R Massive MIMO radios. After this, the brand will launch intelligent network automation solutions for Samsung just to control life cycle management, from deployment and operation to maintenance. This O-RAN-compliant automation solution offers the power to accelerate innovative software-based network rollouts by authorizing the automated deployment of many network sites together.